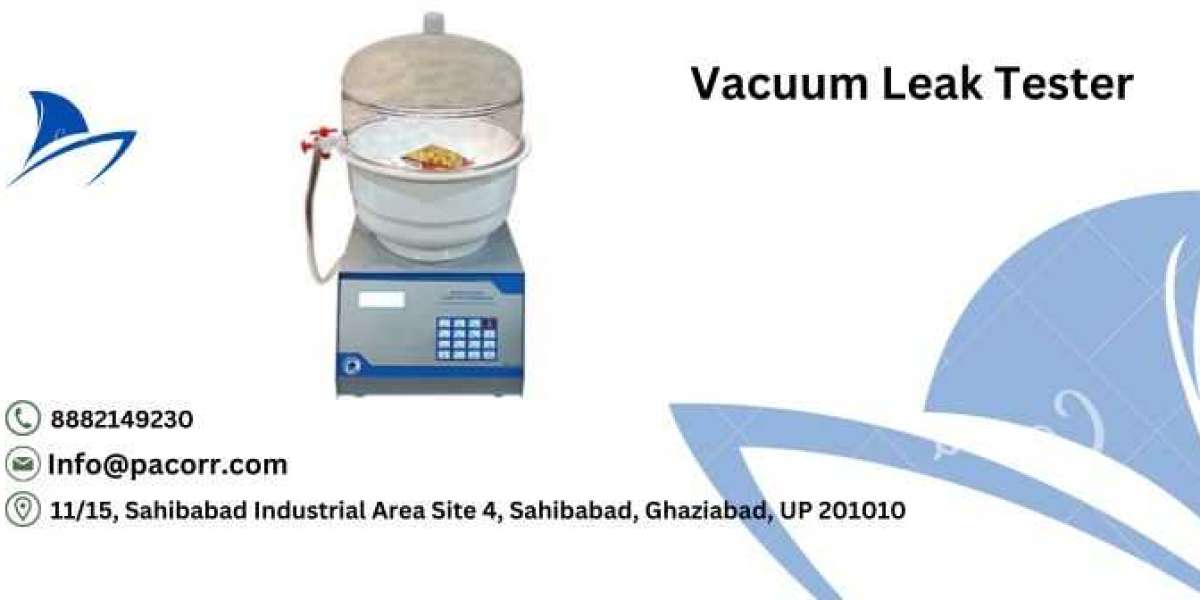

What is a Vacuum Leak Tester?

A Vacuum Leak Tester is an instrument used to check for leaks in sealed packaging by creating a vacuum environment around the product. The purpose is to simulate conditions the package might encounter during transportation and storage, ensuring the integrity of the seal and the product within.

How Does a Vacuum Leak Tester Work?

Vacuum Leak Tester work by placing the product inside a sealed chamber, from which air is removed to create a vacuum. The device then monitors the system for any changes in pressure, which would indicate a leak. Advanced models use sensors and software to provide quantitative data on the size and rate of the leak.

Why is Leak Testing Important?

Leak testing is critical for several reasons:

Product Quality: Ensures the product inside the packaging remains uncontaminated and safe for consumer use.

Shelf Life: Properly sealed products last longer, reducing waste and improving customer satisfaction.

Regulatory Compliance: Many industries have strict regulations regarding packaging integrity, which leak testing helps fulfil.

What Types of Packaging Can Be Tested?

Vacuum Leak Tester are versatile and can test a wide range of packaging types, including:

Flexible packaging (bags, pouches)

Rigid containers (bottles, jars)

Blister packs

Sealed trays

What Industries Benefit from Vacuum Leak Testing?

Many industries benefit from vacuum leak testing, including:

Food and Beverage: Ensures packaging is airtight to preserve freshness and prevent contamination.

Pharmaceuticals: Guarantees the integrity of drug packaging, crucial for safety and efficacy.

Cosmetics: Helps maintain the quality and longevity of products.

Electronics: Protects components from moisture and dust.

How to Choose the Right Vacuum Leak Tester?

Selecting the right Vacuum Leak Tester involves considering several factors:

Package Type: Ensure the device is suitable for the types of packages you need to test.

Sensitivity: Choose a tester with the appropriate sensitivity level for your requirements.

Usability: Look for devices with user-friendly interfaces and features that streamline the testing process.

Durability and Support: opt for robust devices backed by comprehensive support and warranty options.

Conclusion

Vacuum Leak Tester is a critical quality control measure across various industries, ensuring that products meet the highest standards of safety, integrity, and durability. By understanding the basics of how these testers work and their importance, businesses can make informed decisions on implementing the right testing solutions. For those looking to dive deeper into vacuum leak testing solutions, Pacorr.com offers a wealth of resources, expertise, and state-of-the-art equipment tailored to meet your specific needs.